Webinar Topics & Speakers

Hydraulic rerates

Aaron Burton - Lead Field Engineer - Pump Services

Pump performance and efficiencies play a much larger role than ever before when it comes to reliability and total cost of ownership. Over time, the requirements of a pumping system will likely change to meet new demands placed on the operating unit. These changes may place a pump operating point at an inefficient location on the pump curve or produce increased vibration; leading to shorter MTBR. Whether the pumping unit has requirements for more flow or less flow, there are often several options to change the original hydraulic profile of the pump to meet the new demands. This presentation will outline the most common practices and provide some examples of these hydraulic rerates that are currently in operation now.

Troubleshooting and compressor reliability enhancements

Jim Goode - Technical Advisor, Central Engineering - Turbomachinery Services

Most equipment problems can be tied to basic mechanical failures. So before you get out the biggest and fanciest tool, start with troubleshooting basics. With todayís technology equipment, reliability can be vastly improved leading to reduced down time and longer life cycles. This topic will cover troubleshooting basics and equipment enhancements.

Critical motor repair including synchronous HV repair

Joe Sedberry - General Manager, Operations - Electro Mechanical Services

Critical motors come in all types and sizes. However itís the large horsepower machines we tend to think of when we are identifying what motors are critical to an operation. In this segment we will discuss typical failures and repair methods for all of your critical motors.

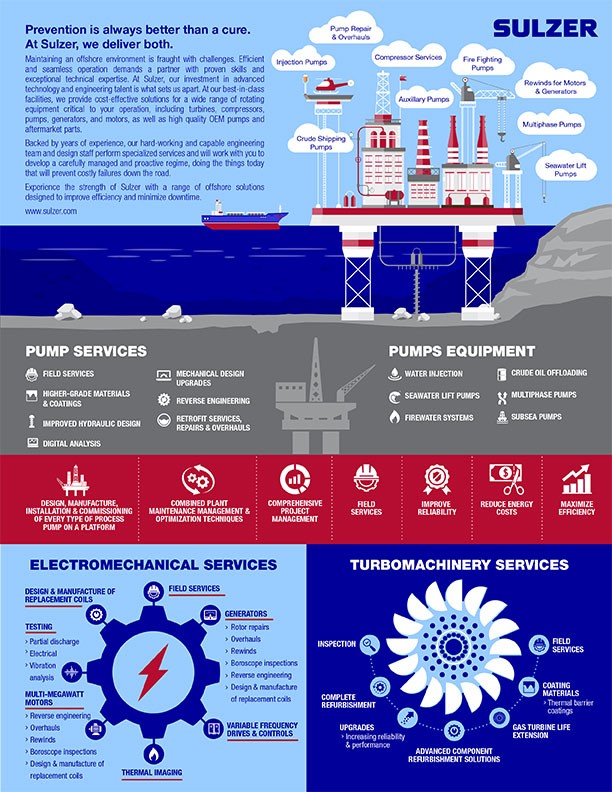

Prevention is always better than a cure.

At Sulzer, we deliver both.

Contact us today at

RES_AME_Marketing@Sulzer.com

|

|

|

|